Stage Curtains

Superior Construction, Superior Drapes.

All our drapery is hand made by our in-house sewing team.

The difference is in the detail. Our pleats provide superior fullness and look, see the difference. Our jute features black tear resistant fabric, way stronger than traditional canvas.

We fold over a full foot on both stage facing and outside sides (Figure 1), it provides great protection from damage and allows swapping of panels later.

Fabric Types

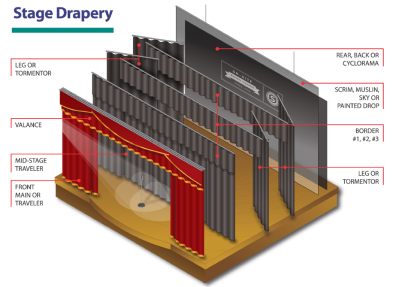

Velour: This is the typical stage drapery fabric it provides excellent light and sound absorption. Used mostly for Main Draws and Valances (Figure 2). Velours can be made from synthetics or cotton. Velours come in a variety of colours (Figure 3).

Commando or Duvetyn: Less expensive than velours and is mainly used for legs, rears and borders (Figure 2). Typically black, but also available in colors (Figure 4). Commando is made from cotton and treated with flame retardant such that it meets Fire Code Standards of flammability. We exclusively sell 16oz Commando, otherwise known as heavy commando, for a more durable, long lasting drape.

All Natural Fabrics

We don't like synthetics. We believe theater drapes should be made from cotton, pure and natural.

Why don't synthetics feel right to us?

- Synthetic fabrics have environmental issues associated with the raw materials used (coal & oil), manufacturing process and when washed, microplastics are flushed into our water system. A recent study found 6 kg of polyester washed shed over 496,030 fibres. Yuck!

- Nothing provides the same look as cotton. A good velour nap provides superior light absorption & sheen. Most theatre professionals insist on only high quality cotton velours, why settle for second best?

- Sound Absorption, heavy weight cotton fabrics provide the best acoustical absorption which is a critical part of what drapes do.

- With Synthetics, you are never really sure what you are getting. Synthetic materials introduce a large base of countries who can now manufacture fabrics, whereas when it was limited to cotton, the sources were well known. We have seen an influx of low cost, low quality synthetics enter the market recently. These fabrics do not wear well, attract static cling, and in some cases fail the fire code testing right out of the box, despite the paperwork insisting it is not flammable. We don't play games with quality or safety.

Fire Code

Theatre Stage Curtains present a significant risk of fire. Stage Drapes can ignite quickly as the materials used in the majority of stage curtains are not inherently flame retardant, even inherently flame retardant fabrics become highly combustible when dirty. The presence of hot lights and various props can significantly increase the risk of fire.

As a result, the Fire Code requires facilities have flame retardant applied to all stage drapes and maintain a Certificate of Flame Retardant Testing on file. Typically, drapes when purchased new have been treated already with Flame Retardant, however, Flame Retardant typically needs to be re-applied every 3-5 years to remain effective. In addition, if drapes have become wet or have been washed or dry cleaned, the flame retardant properties will have been removed.